SS Nonwoven Spunbond Machine

Full automatic YH-1600MM-4200MM pp non woven fabric making machine

Our SS Nonwoven Fabric Production Line Equipment use state-of-the-art technology that produces high-quality nonwoven fabrics. The equipment is designed to meet the growing demand for nonwoven fabrics in various industries, including agriculture, healthcare, construction, and packaging. This equipment is easy to operate, energy-efficient, and produces nonwoven fabrics of different thicknesses and densities.

Our SS spunbond nonwoven production equipment is a highly advanced and efficient technology used for the manufacture of nonwoven fabrics. It offers numerous advantages and features that make it a popular choice among manufacturers across various industries.We'll intruduce the advantages and features of SS nonwoven production equipment, machine's applications, product description, mechanical structure, and

other related information.

Advantages and Features:

1. High production efficiency: SS nonwoven production equipment has a high production speed and can produce a large quantity of nonwoven fabrics in a short period of time.

2. Excellent quality: The nonwoven fabrics produced by SS nonwoven production equipment have excellent quality, high strength, and durability.

3. Versatility: SS nonwoven production equipment can produce a wide range of nonwoven fabrics with different properties and characteristics, such as hydrophobic, hydrophilic, breathable, and more.

4. Low energy consumption: SS nonwoven production equipment has a low energy consumption and can save a significant amount of energy, making it an eco-friendly option.

5. Easy operation: SS nonwoven production equipment is easy to operate and requires minimal maintenance, reducing downtime and increasing productivity.

Applications:

SS nonwoven production equipment is widely used in various industries, including:

1. Medical: Nonwoven fabrics produced by SS nonwoven production equipment are used in the manufacture of surgical gowns, face masks, and other medical products.

2. Agriculture: Nonwoven fabrics produced by SS nonwoven production equipment are used in agriculture for soil protection, crop cover, and weed control.

3. Automotive: Nonwoven fabrics produced by SS nonwoven production equipment are used in the automotive industry for insulation, soundproofing, and filtration.

4. Construction: Nonwoven fabrics produced by SS nonwoven production equipment are used in the construction industry for insulation, roofing, and wall coverings.

Product Description:

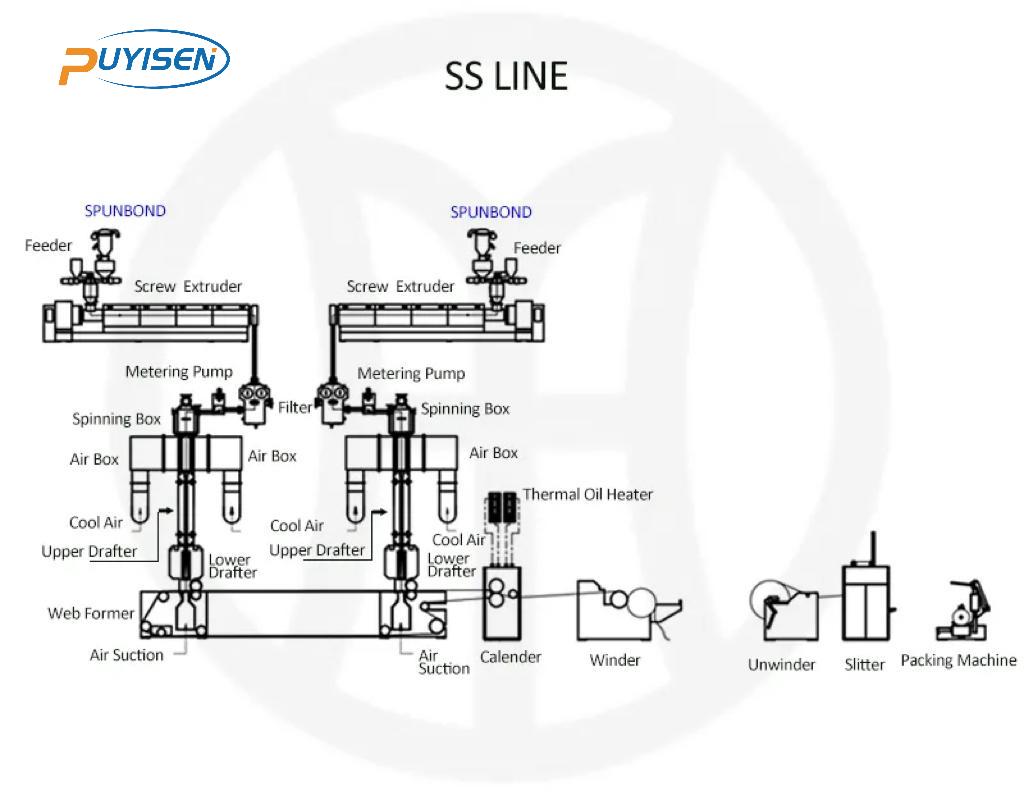

SS nonwoven production equipment consists of several components, including:

1. Extruder: The extruder melts and mixes the raw materials and then extrudes them into filaments.

2. Spinneret: The spinneret is a metal plate with tiny holes that converts the filaments into a web.

3. Quenching chamber: The quenching chamber cools and solidifies the web.

4. Bonding unit: The bonding unit bonds the web together to form a nonwoven fabric.

5. Winding unit: The winding unit rolls the nonwoven fabric into a roll.

Mechanical Structure:

SS nonwoven production equipment has a compact and efficient mechanical structure that consists of several key components, including:

1. Mainframe: The mainframe is the central component that houses all the other components.

2. Control system: The control system controls and monitors the entire production process.

3. Extruder: The extruder is the component that melts and mixes the raw materials.

4. Spinneret: The spinneret is the component that converts the filaments into a web.

5. Quenching chamber: The quenching chamber is the component that cools and solidifies the web.

6. Bonding unit: The bonding unit is the component that bonds the web together.

Summarize:

SS nonwoven production equipment is a highly advanced and efficient technology used for the manufacture of nonwoven fabrics. It offers numerous advantages and features that make it a popular choice among manufacturers across various industries. Its versatility, low energy consumption, and ease of operation make it an eco-friendly and cost-effective option for producing high-quality nonwoven fabrics.

Within one week after everything ready (machine arrival your factory, non woven material, power source, air compressor etc.Prepared)...more