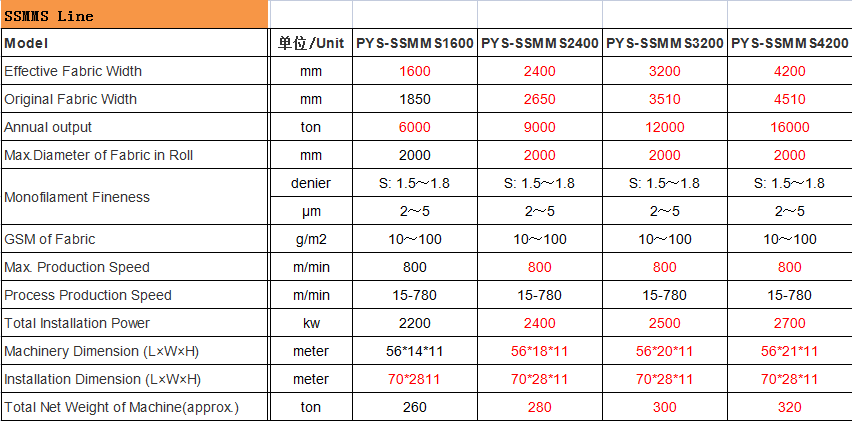

SSMMS Spunbond Nonwoven Fabric Machine

Technical Advantages

1) The whole line is well-structured and easy to operate.

2) The whole line is highly automated.

3) Control elements are of well-know make, high performance and reliable technologies.

4) The whole line are controlled by PLC and operated with touch-screen.

5) The allocation of the main frame and auxiliary equipment can be special designed and adjusted according to customers requirement.

SSMMS Nonwoven Production Line Overview

The SSMMS nonwoven production line is a state-of-the-art manufacturing system that produces high-quality nonwoven fabrics. This production line is known for its superior quality, efficiency, and flexibility, making it a popular choice for a wide range of applications.

Advantages and Features

One of the main advantages of the SSMMS nonwoven production line is its ability to produce fabrics with superior strength, uniformity, and softness. This is achieved through a unique combination of spunbond, meltblown, and spunbond-meltblown-spunbond (SMS) technologies.

The SSMMS production line is also highly efficient, with a high production speed and low energy consumption. This means that it can produce high-quality fabrics at a lower cost than other production methods.

Another key feature of the SSMMS nonwoven production line is its flexibility. It can be customized to produce a wide range of fabrics with different properties, such as hydrophobicity, breathability, and elasticity. This makes it a versatile option for a variety of applications.

Applications

The SSMMS nonwoven production line is used to produce a wide range of products, including:

1. Medical and hygiene products: surgical gowns, drapes, masks, and wipes.

2. Personal care products: diapers, feminine hygiene products, and adult incontinence products.

3. Industrial products: filters, geotextiles, and insulation materials.

4. Packaging materials: shopping bags, food packaging, and protective packaging.

Product Description

The SSMMS nonwoven production line produces fabrics with a weight range of 10-150 gsm and a width of up to 3.2 meters. The fabrics can be customized to meet specific requirements, such as color, texture, and strength.

The fabrics produced by the SSMMS nonwoven production line have a variety of properties, including:

1. High strength and durability

2. Softness and comfort

3. Breathability and moisture management

4. Hydrophobicity and water repellency

5. Elasticity and stretchability

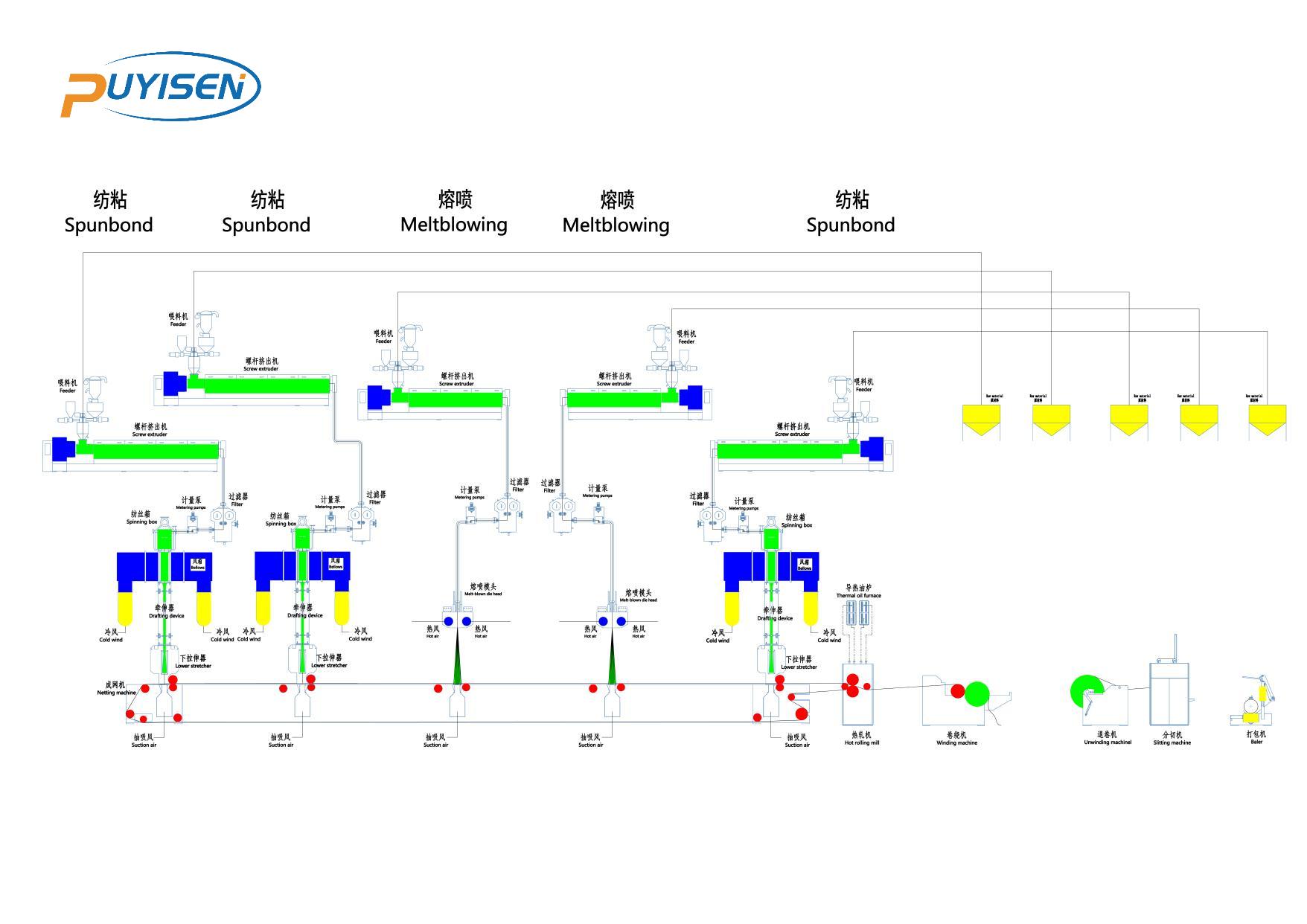

Machine Structure

The SSMMS nonwoven production line consists of several key components, including:

1. Spunbond module: This module produces the base layer of the fabric using spunbond technology.

2. Meltblown module: This module produces the middle layer of the fabric using meltblown technology.

3. SMS module: This module combines the spunbond and meltblown layers to create the final fabric.

4. Winding and cutting module: This module winds the fabric onto a roll and cuts it to the desired width.

Within one week after everything ready (machine arrival your factory, non woven material, power source, air compressor etc.Prepared)...more